We are proud that all our engineers strive to provide the highest standards when performing CNC milling services. At every stage of the project, we adhere to strict quality standards and procedures to ensure that all precision parts that we manufacture have the desired dimensions and tolerances.

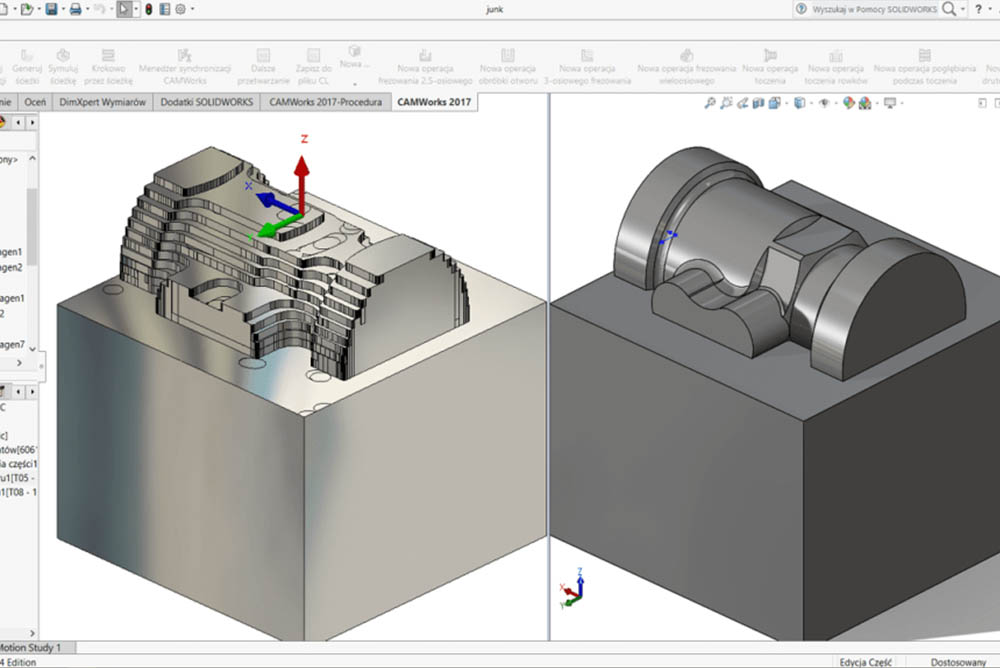

Investments in the latest precision engineering technology allow us to create high-quality precision parts to order. By providing the level of service you expect, we work to be proud of every project we implement.

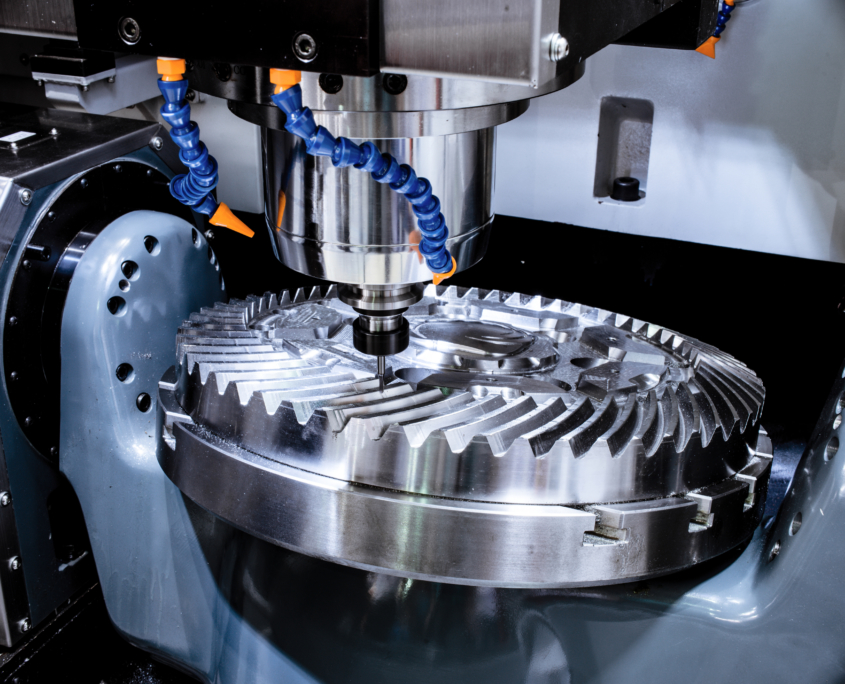

The CNC machine we use can perform a huge number of complex processes in one accurate operation, which allows us to create more complex parts on the customer’s order, with greater precision and saving time.