CAMWorks is advanced and intuitive CAM software that helps increase productivity using best-in-class technology and adaptable automation tools to maximize CNC machining efficiency.

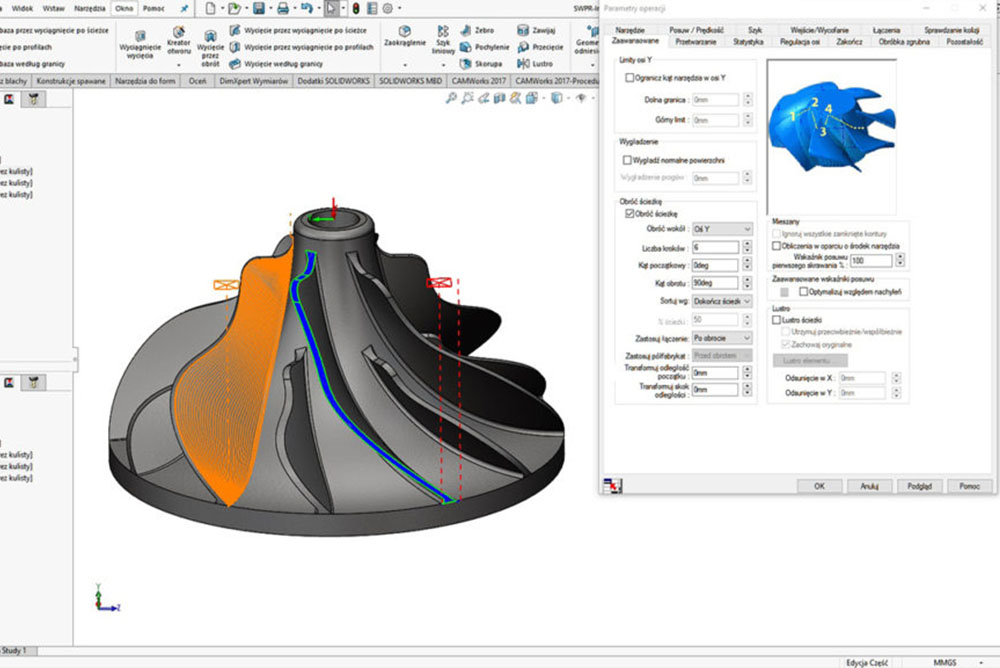

CAMWorks is able to provide optimized technology for multi-axis CNC machines that will increase the efficiency and safety of the machining process. Our team responsible for CAM implementations will prepare dedicated postprocessors for specific machines.

CAMWorks 2019 is the most advanced CAM software available, combining proven production-based CAM technology, automatic function recognition and rule-based and tolerance machining to use MBD and PMI technology to intelligently automate the manufacturing process.