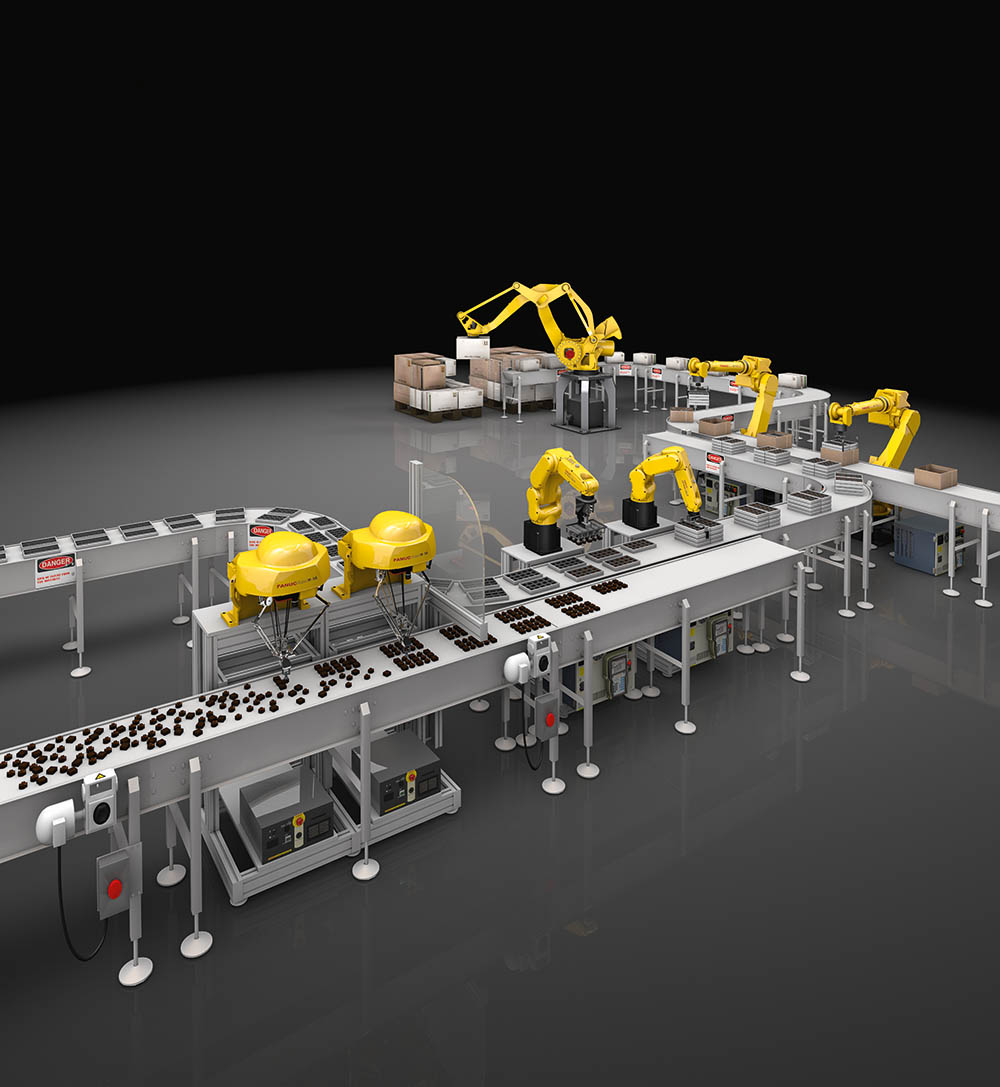

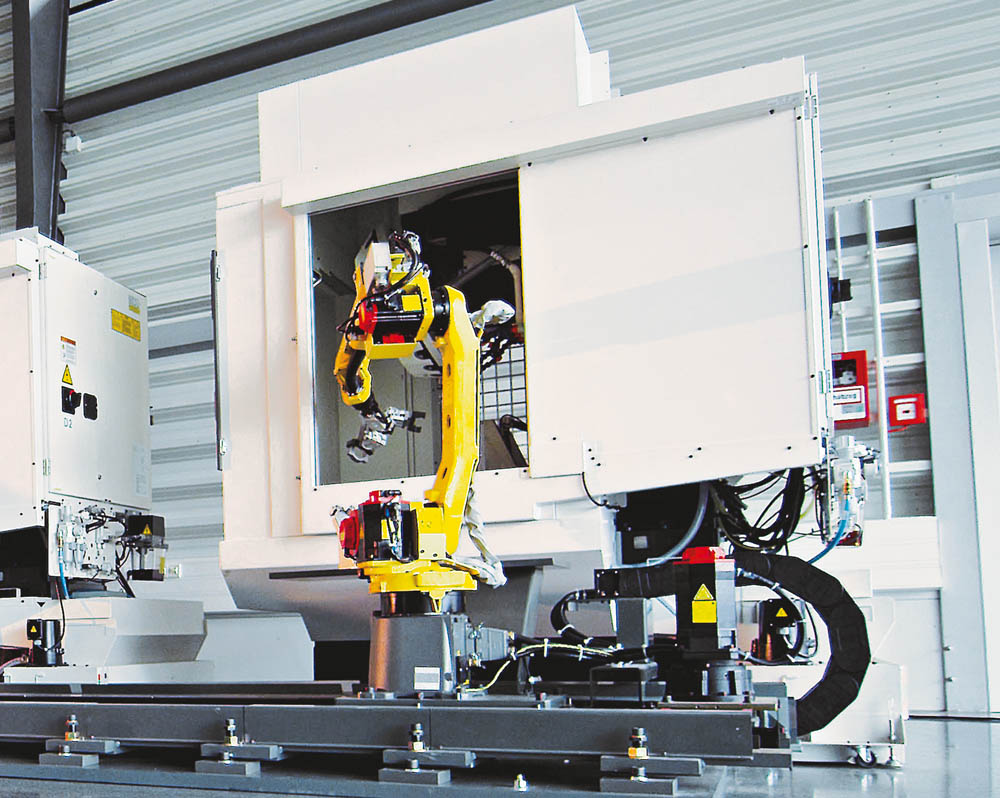

Automation of work processes, precision, repeatability, resistance to disruptive working conditions, high performance and the possibility of continuous operation are the basic elements which must be met in a production company in order for it to be competitive and able to develop in a stable way. Industrial robots have been helping to meet these requirements since the middle of the last century, and are currently supporting the implementation of Industry 4.0. The automotive and electronics industries could hardly operate without industrial robots. Robots are more and more boldly entering new industries, replacing humans. It is no longer only handling, welding, cutting, palletising or packaging that are robotised processes. Increasingly, companies are looking for automation and robotisation for milling, grinding, deburring or replacing parts on machining centres.

Implementing with our company a project of introducing robotic workstations, SOLIDEXPERT specialists will help in the digital transformation and the industrial revolution 4.0 of your company. We specialise in building robotic stations for processes related to surface finish and wear treatment. We welcome you to cooperate with us!